Circular Economy

The concept of circular economy has been part of our culture even before the term was mainstreamed. Since establishing a circular economy approach is part of our topmost sustainability goals, we recognize the importance of utilizing our resources sustainably, through better efficiency and the reduction of waste.

We recognize that the Company consumes a large amount of both renewable and non-renewable resources throughout its various business activities. With our continued push toward nation building, our demand for resources will inevitably increase as the Company grows. To address this, we aim to transform our business model and to “close the loop” in order to shrink our material footprint and to prevent any adverse impacts on the environment. We have adopted practices of reduction, recycling, and recovery, as well as developed programs and policies. We strive to become more efficient in the materials we use and reduce the amount of waste we generate.

Materials and Waste

Materials Management

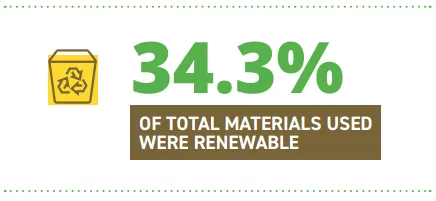

We used 15.7 million MT of materials in 2022 for our operations. Of this, 65.7% are non-renewable materials and the remaining 34.3% are renewable materials. Most material inputs were used by Petron and NCC in the form of crude oil, limestone, and clinker. We were able to recycle 442 thousand MT of the materials we used. These recycled items consisted mostly of glass bottles retrieved at post-consumer stage, for reuse by our beverage businesses, or broken glass cullets recycled by our packaging business. Also recycled are coal ash from SMGP’s power plants used as raw material in the cement production process of NCC. In 2022, NCC successfully recycled 150,194 MT of coal ash as inputs for cement.

We have adopted practices of reduction, recycling, and recovery, as well as developed programs and policies. We strive to become more efficient in the materials we use and reduce the amount of waste we generate.

Solid Waste Management

We understand the importance of proper waste management to our business operations. The Company already has ongoing initiatives designed to reduce the amount of waste we generate. We accomplish this by finding ways to recirculate byproducts and materials at their highest value.

The Company generated 330.6 thousand MT of solid waste in 2022, of which we were able to redirect approximately 90.3%. Waste classified as spent grain and spent yeast, generated by SMFB, has the largest contribution to our solid waste. Spent grain and spent yeast are protein-rich materials used by our animal feeds business, providing nutrients required by poultry and livestock for maintenance, growth, and reproduction.

The second largest contributors were glass, cullets, and jars used for our bottles and beverages, which we were able to reuse or recycle. SMB has in place a returnable glass bottle system that encourages customers to return empty bottles, which the company then retrieves from retail outlets. On the other hand, GSMI has a robust bottle retrieval system through a network of territorial bottle suppliers. Recovered bottles are subjected to thorough inspection and quality control protocols to ensure safety for reuse. Both systems greatly reduce the need to manufacture new bottles, minimizing product cost and conserving material resources.

Meanwhile, sludge and slop from wastewater treatment facilities, and manure from SMF’s poultry and pig farms are converted to organic fertilizer. Metal scraps, plastic waste and other non-hazardous waste that cannot be used in our operations are sold to recyclers. The remaining solid waste that could not be recycled is sent to landfills.

The Company is prepared to be fully compliant with the Republic Act No. 11898, the Extended Producer Responsibility (EPR) Act of 2022, which became effective on August 13, 2022. The law requires obliged enterprises, such as SMFB, to recover and divert at least 20% of their 2022 plastic packaging footprint by the end of 2023 and increase this annually up to 80% by the end of 2028. In future reports, we will be providing information on their compliance with EPR.

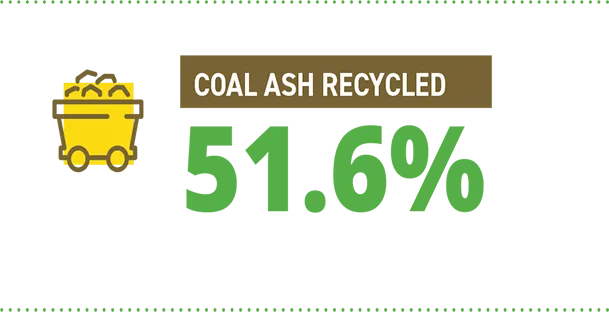

Coal Ash Management

We generated a total of 566.6 thousand MT of coal combustion residuals from our power generators. We were able to redirect a portion of the coal ash and reuse these in our cement manufacturing process. The CCR that were not reused in our cement plants were sent to external companies for further recycling. As a result, we were able to recycle 51.6% of our generated coal ash in 2022.

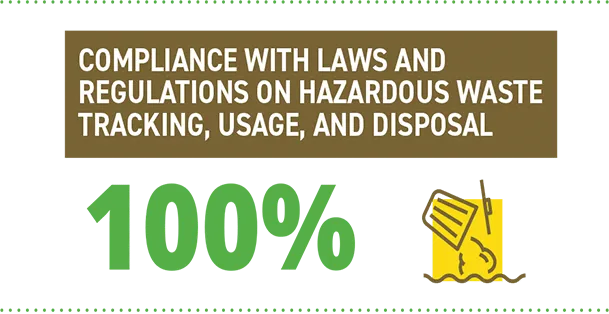

Hazardous Waste Management

The Company generated 8.9 thousand MT of hazardous waste in 2022. Our hazardous waste is mostly made up of used oil and sludge from our vehicles and generators, as well as reactive chemical waste from various manufacturing processes. We were able to divert 36.2% of our total hazardous waste generated.

Hazardous waste is strictly regulated by environmental regulatory agencies. We abide by all laws and regulations regarding hazardous waste tracking, usage, and disposal. The Company has established a hazardous waste and solid waste management system that monitors the inventory, generation, and disposal of waste. Our Pollution Control Officers are tasked with data management and ensuring governmental compliance.