Climate Change Action

When San Miguel began its transformation journey from a food, beverage, and packaging company to a diversified conglomerate with investments in fuel, power and infrastructure, the stimulus was the need to propel the country’s economic growth by providing greater access to energy resources and an infrastructure that allowed industries to be more competitive. The transformation generated a larger environmental footprint with the use of fossil fuels and the development of parcels of land into infrastructure projects, alongside increased water and raw material usage and waste generation.

Cognizant of the huge responsibility we have taken on, San Miguel is committing to twin goals in relation to the environment. First, we aim to establish a Circular Economy Approach by 2040, ensuring that more of the waste we generate is reused, recycled, or repurposed, and increasing the component of recycled materials used in our production processes. Second, in response to the urgent global call to cut carbon emissions, we align to the goal of Net Zero by 2050. This is not a commitment made lightly as we consider the balance between the need for more accessible and affordable energy and the viability and reliability of clean energy sources.

Our sustainability governance structure plays a critical role in making sure that San Miguel is pursuing a sustainable business model and making a positive impact on society and the environment.

Following are the baseline data on our environmental footprint and the ongoing and planned initiatives to forge ahead toward our goals.

Greenhouse Gas (GHG) Emissions

We place paramount importance on mitigating our GHG emissions. We recognize the profound impacts that emissions from our businesses and operations have on climate change adaptation and mitigation. As a result, we have embarked on a pivotal journey to significantly reduce our GHG emissions to Net Zero by 2050.

An indispensable step toward achieving this goal is to accurately measure our emissions in line with globally accepted GHG accounting and reporting standards. Thus, we use the GHG Protocol—the most comprehensive global standardized framework to measure GHG emissions, developed by the World Resources Institute and the World Business Council for Sustainable Development—to account for and manage emissions across all activities in our Group.

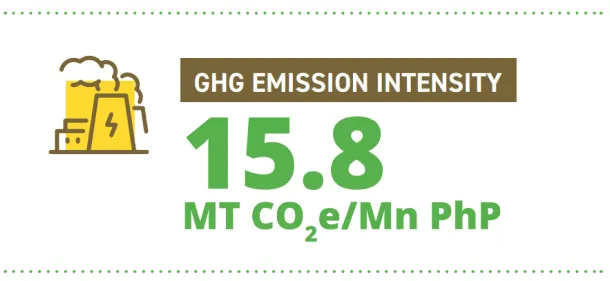

In 2022, our GHG emissions intensity—or the amount of GHG emissions that we generate for every peso of our sales—is 15.81 MT CO2e/ Mn PhP. Our Power, Oil and Fuel, and Cement businesses are the largest contributors to our emissions intensity. Our aim is to reduce our emissions intensity by decoupling our business growth from the growth in our emissions. This we will do by employing low carbon solutions and initiatives across our various businesses and operations.

Our power business is one of the major contributors to our nation’s economic development. The energy it supplies spurs the growth of thousands of businesses, infrastructure, and investments nationwide. Cognizant of this responsibility, we uphold the government’s thrust to provide reliable and affordable energy to all Filipinos. In the same breath, we also support the country’s plan to have a just transition to more renewable sources of energy. Hence, we actively seek to diversify our power portfolio toward cleaner energy sources, while at the same time ensuring energy security and affordability for our customers.

We plan to increase our 1,200 MW liquefied natural gas (LNG) and will complete 1,000 MWh of combined BESS projects nationwide, which together contribute to increasing the diversity of our portfolio. The planned expansion of our gas-fired generation capacity and BESS reflects our overall commitment to reduce our carbon emissions and support the government’s climate policies and objectives, including the Philippines’ Nationally Determined Contributions under the Paris Agreement.

Also, we have taken crucial steps to help the country’s transition to renewable energy. Our combined 563 MW hydro power plant capacity is a first step toward this direction. Moreover, we are developing a portfolio of solar power projects with an initial aggregate capacity of 800 MW across various sites in Luzon including the provinces of Bataan and Isabela. The proposed solar projects will be situated in areas with moderate to high photovoltaic potential.

In February and August 2022, we obtained a Certificate of Registration from the DOE as a renewable energy (RE) developer for a solar project located in Bataan and have entered into a Solar Energy Operating Contract (221MWp) with the DOE for the development and operation of RE projects using solar energy as a renewable source (“Bataan Solar Project”). The lease agreements for the property in Bataan and in Isabela where the solar projects will be located have already been executed. Currently, the Bataan Solar Project is in the pre-development stage.

Together, these initiatives serve our overarching goal of minimizing emissions from our power business.

Meanwhile, we have been reducing our carbon emissions in our Bataan oil refinery through various initiatives, such as plant reconfiguration, replacement of thermal power plants with steam generating facilities, and recovery and maximized utilization of fuel gas in the refinery. Furthermore, our Bataan refinery and fuel product terminals have Integrated Management Systems (IMS) certification. The IMS certification we have earned combines some of the most rigorous international standards on environmental management (ISO 14001:2015), quality management (ISO 9001:2015), and occupational health and safety management (ISO 45001:2018) into a single, comprehensive, and harmonized management system. This unified approach has created important synergies, a stronger foundation for our business and facilities, and has enhanced our overall sustainability and competitiveness in the industry.

In our cement business, a substantial source of emissions is clinker production because of the carbon released by limestone and the energy required in the process. Thus, we have leveraged new technologies to develop cement products that have lower clinker factor but have the same concrete strength. To reduce the clinker component in our products, we utilize supplementary cementitious materials like natural pozzolan and fly ash. Despite the lower clinker factor, our cement products still exceed industry benchmarks and remain versatile and economical building materials used in a wide variety of commercial and industrial applications.

We will elevate our energy conservation initiatives to include the expanded use of solar and biomass to address our energy requirements. We will also monitor, assess, and employ new energy-efficient processes and technologies that will enable us to minimize our emissions.

To further lessen our emissions from our cement business, we are also employing circularity in our operations. In 2022, our cement plant generated 4.58 MT of plastic waste from its operations and third-party contractors. To dispose of this waste responsibly and to reduce the plant’s reliance on traditional fuels for its operations, the plastic waste was injected at the pyro-processing stage of cement production, harnessing its useful heat for the manufacture of clinker. At the same time, NCC recognizes that it can do more to reduce its dependence on traditional fuel sources. Currently, the company is tapping into a specific technology that would enable a higher percentage of waste to be used as alternative fuel in the pyro-processing stage. By substituting traditional fuel with alternative fuels like plastics, municipal solid waste, rubbers, and used tires, NCC aims to cut its traditional fuel usage by up to 50 percent.

Throughout the years, our cement business has garnered acclaim for managing environmental impacts and meeting the requirements set by governing agencies like the Environmental Management Bureau (EMB) and Mines and Geosciences Bureau. It was awarded by the DENR with the Presidential Mineral Industry Environmental Platinum Award in recognition of its excellent environmental and safety performance as well as its community development programs. Our cement business also has an IMS certification, which highlights its dedication to responsible operations and its commitment to meeting international standards for sustainable practices.

We uphold the government’s thrust to provide reliable and affordable energy to all Filipinos. In the same breath, we also support the country’s plan to have a just transition to more renewable sources of energy.

We are also leveraging innovation across other parts of our businesses to further reduce our GHG emissions intensity. In our Beer and Spirits divisions, we recover the carbon dioxide (CO2) from the fermentation process and purify it for use in the manufacturing process. We sell any excess as industrial- and food-grade CO2 to other companies. To treat wastewater, we utilize anaerobic reactors which significantly reduce our carbon emissions from pure aerobic treatment. Moreover, our Beer and Spirits businesses have long-established initiatives to recover methane from the anaerobic treatment of wastewater and use the methane as biogas to fire up our boilers, thereby decreasing our consumption of fuel oil. Finally, we add limestone in our coal-fired boilers to reduce GHG emissions and employ wet scrubbers to reduce pollution. These key programs and initiatives embody our responsible stewardship not only toward our customers but also toward the environment. It underscores our commitment to sustainable development, as we have made every effort to go beyond compliance. We know there is still more to do, but we believe that we are on the right path toward achieving our goal of Net Zero.

Moreover, we continue to benefit from the energy reduction and conservation measures we have implemented across all our businesses. These include the creation of energy conservation teams in each of our business units, the inclusion of power index in key performance indicators of our businesses, the conversion of our lighting to LED, the replacement of our air-conditioning units into inverter type, and the use of solar panels for our streetlights and for our office and warehouse lighting.

In our Properties business, we are employing green business solutions to reduce our energy consumption. Examples of these initiatives are the orientation of our buildings to maximize natural lighting and ventilation and the use of energy-efficient systems and equipment.

We will elevate our energy conservation initiatives to include the expanded use of solar and biomass to address our energy requirements. We will also monitor, assess, and employ new energy-efficient processes and technologies that will enable us to minimize our emissions.

Non-GHG Emissions

The health and safety of the people in our host communities is top priority for San Miguel. Hence, we protect the quality of the air the residents of our host communities breathe.

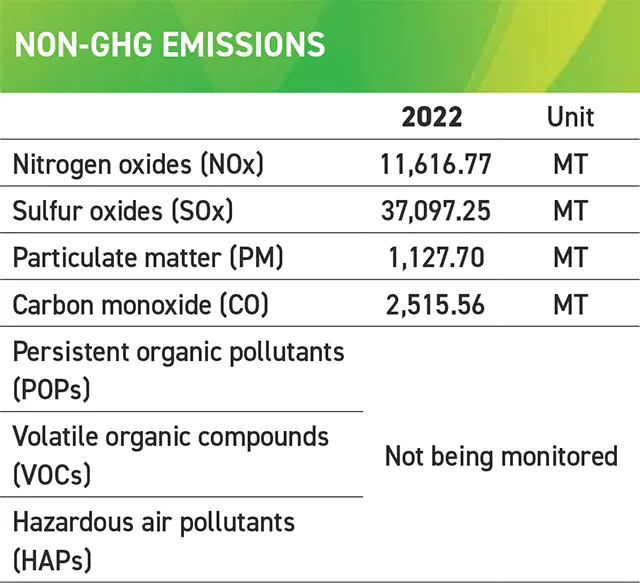

Our non-GHG emissions come primarily from our thermal power plants, oil refining plant, cement plants, and to some extent, from fuel consumption of our boilers, cookers, vehicles, and generators.

Our power plants have consistently maintained emissions way below the limits set for SOx, NOx, and PM set by the DENR and World Bank by investing in the most advanced and efficient technologies.

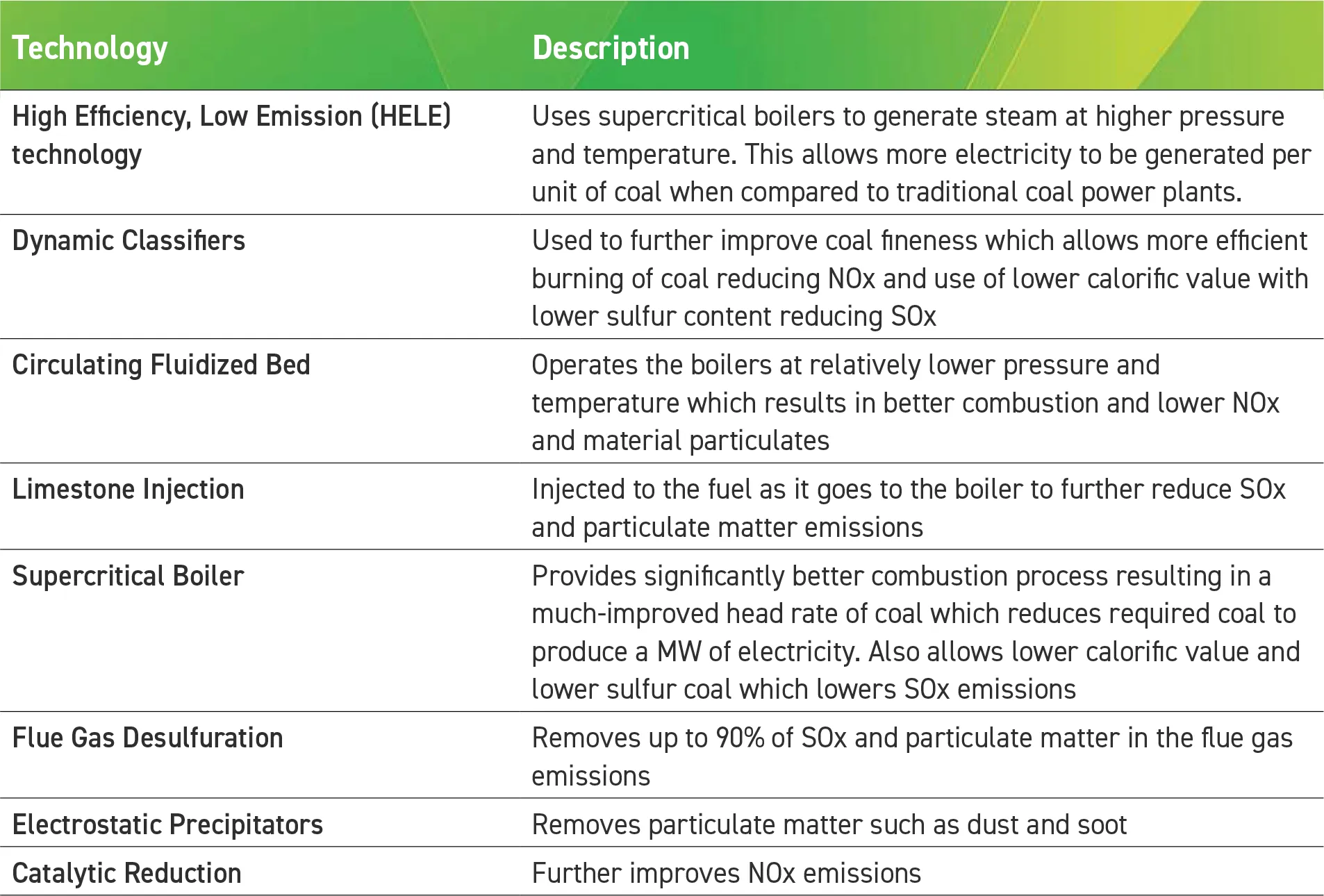

Being the primary source of our non-GHG emissions, our thermal power plants track their emissions religiously through daily emissions testing and make sure that they are well within the limits set by the DENR and the World Bank. Our thermal power plants have consistently maintained emissions way below the limits set for SOx, NOx, and PM based on data collected over the past several years. We have achieved this by investing in the most advanced and efficient technologies on the market to make our power plants environmentally friendly. We have leveraged the following forefront technologies for our power plants: