Balancing Act

SMGP maintains a diversified portfolio of both traditional and renewable power facilities. Even at the beginning of implementing our next-stage strategies to achieve a lower carbon future—such as investing in battery storage and renewable capacities on our way to net zero by 2050—coal power remains an indispensable resource for the Philippines in the foreseeable future.

We have long recognized the crucial importance of balancing our developing nation’s need for reliable and affordable baseload energy with the need to minimize our environmental impact. Our approach, particularly for coal power, has been to utilize the latest technologies that can drastically cut harmful emissions.

HELE Technology

HELE technologies are a type of cutting-edge coal technology designed to increase production efficiency while lowering the GHG and non-GHG emissions per amount of power generated by our coal-fired power plants.

It can be achieved through a supercritical, ultrasupercritical, or advanced ultra-supercritical technology that allows the power plants to run at higher temperatures and pressures to bring about more thorough fuel combustion, resulting in increased efficiency and lower CO2 emissions. This enables coal-fired power plants to use less fuel to produce the same amount of energy, ultimately resulting in minimized environmental impact.

HELE technologies also encompass other advanced technologies, such as improved coal drying and cleaning processes, advanced air pollution control systems that aids in lowering sulfur and nitrogen oxide emissions, and improved materials for the high-temperature components in facilities.

CFB Technology

Meanwhile, circulating fluidized bed (CFB) technology, used in the combustion of solid fuels, such as coal and biomass, is another way we produce power in a more environment-friendly manner.

In a CFB, solid fuel is introduced into a furnace with bed material, such as sand or other particulate matter. Fans supply excess oxygen into the furnace so that complete combustion can take place. This causes the bed material to flow continuously inside the furnace and be kept in suspension by the flow of hot gases produced by the combustion of the fuel. This creates a fluidized bed resembling boiling liquid, allowing solid fuel particles to move freely, promoting mixing and heat transfer. The hot gases are then circulated back through the bed to maintain the fluidized state, hence the name “circulating fluidized bed.”

Improving combustion efficiency and lowering emissions of pollutants like SOx and NOx are some of the main benefits of CFB. Additionally, CFBs are a flexible and eco-friendly technology because they can be easily retrofitted with scrubbers to remove pollutants. CFB’s operating furnace temperature is between 850 and 950 degrees Celsius, which is just enough for complete combustion. This means that NOx cannot be produced in the furnace because that would require furnace temperatures to reach 1200 to 1300 degrees Celsius. In addition, limestone is injected into the system to capture the generated SOx as a byproduct of the combustion process.

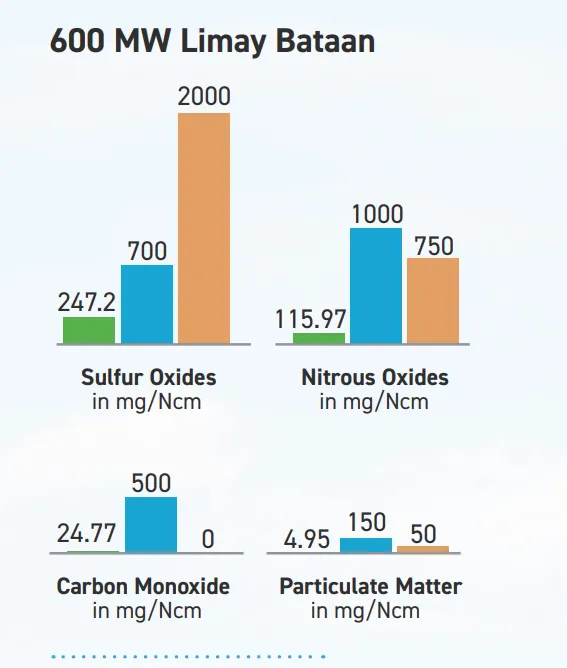

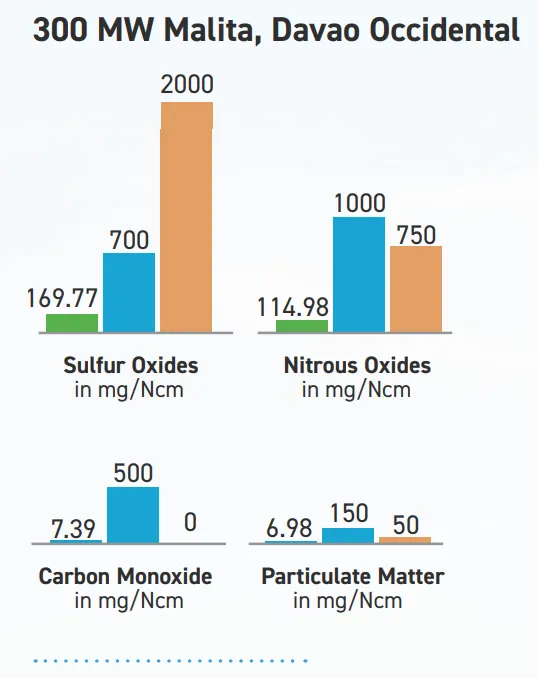

HELE and CFB Technologies have been critical to minimizing the impacts that our coal power facilities have on the environment. Our Limay, Bataan and Malita, Davao Occidental plants, with 600 MW and 300 MW capacities, respectively, are CFBs. A third CFB facility built in Mariveles, Bataan, with an installed capacity of 600 MW, is also set to come online in 2023.

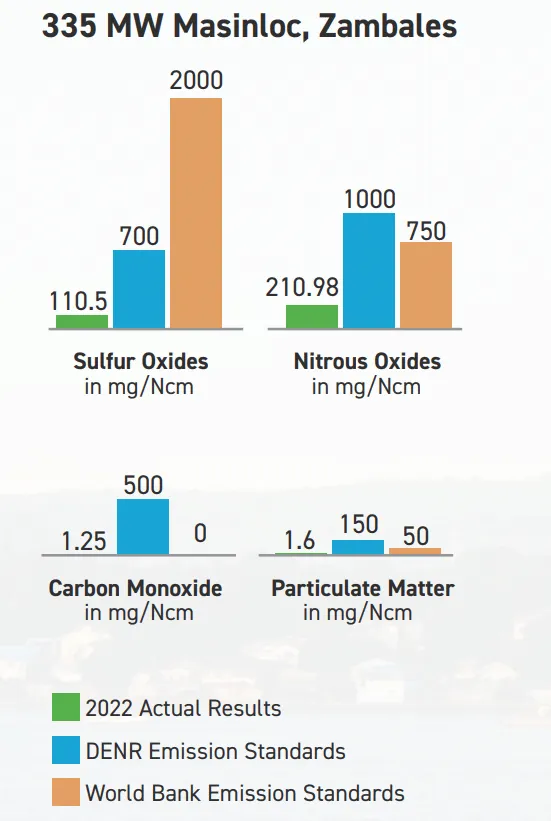

In Masinloc, SMGP operates a 335 MW supercritical coal-fired power plant. Construction is also ongoing on another supercritical plant, which would use less fuel than the conventional power plants, for the optimum generated amount of electricity.