Customer Welfare and Responsibility

Across the diverse business units of San Miguel, one of our priority responsibilities is to ensure the health and safety of our customers. This is a cornerstone upon which our brands have built their reputation and gained the trust of consumers. The key elements of our customer welfare and responsibility program vary according to the nature of each business.

For SMFB, compliance with the regulations of the Food and Drug Administration (FDA) is primary. This includes obtaining a License to Operate for each production facility, Certificates of Product Registration, and compliance with mandatory labelling requirements such as product name, manufacturer’s name and address, nutrition information, list of ingredients, allergen declaration, serving size, net content, lot/batch number, and manufacturing and expiration dates. If applicable, storage and handling conditions, and directions for use are indicated. Additional label markings such as vitamin fortification, low calorie, low-alcohol or no preservatives are also validated and approved by FDA. Each business monitors new guidelines released periodically by the FDA and ensures that product development personnel are informed and trained in the required compliance measures.

Prior to releasing products to market, the company diligently conducts assessment of all ingredients used in product formulations, conducts sensory evaluation with respondents matching their target market, and establishes shelf life of each product. Standard parameters of all raw materials, finished goods and packaging are fully documented. Once in the market, samples from each production batch are retained in the manufacturing plant for reference in case of any product complaint that may arise.

For Food in particular, efforts are ongoing to improve the nutritional value of our products. Recent declarations have linked obesity and non-communicable diseases such as hypertension and diabetes to processed food. To address this concern, the Food Group has been working on ways to improve the nutritional quality of its products, including fortification with vitamins and minerals, reformulation to reduce sodium and preservatives, and the launch of plant-based food. The reformulation process is painstaking and iterative as it aims to achieve target nutritional values while preserving the taste that consumers are accustomed to.

The marketing of consumer goods is likewise subject to certain regulations, more so for alcoholic beverages. All the advertising materials released through media and on digital platforms comply with the requirements of Ad Standards Council, a self-regulating organization that aims to safeguard truth in advertising and give paramount consideration to the consumer’s interest. This includes a one second frame at the end of each commercial reminding the viewer to “Drink Responsibly.” The same caution is present in all outdoor advertising and merchandising materials. Thus, we do our part not to promote excessive drinking but capitalize on brand equity to promote our products.

For our cement business, NCC follows Philippine National Standards (PNS) in labelling its products. This includes product classification, specification and application, trade name, trademark of the manufacturer, batch identification number, and information on disposal of packaging, which are in accordance with PNS 07:2018, PNS 63:2019, and PNS ASTM C91:2005.

For infrastructure, a Road Safety Audit Report is produced based on two components, data collection and data evaluation. The audited project (e.g., Skyway, NAIAx, SLEX, TPLEX, STAR Tollway) must abide by several laws and regulations, including those relating to the environment, public health, safety, municipal and provincial requirements, and internal performance standards. Laws that address process safety management, right-to-know issues, or environmental management are examples of governmental controls.

The organization and the Toll Regulatory Board (TRB) jointly inspect the tollways during an initial phase while driving a van equipped with a dashboard camera. TRB then reviews the video footage to assess the requirements for signages, their proper placement and categorization, the presence of hazardous items, and other safety-related issues. Through these parameters and procedures, the organization can then ensure safer and more convenient road use for motorists.

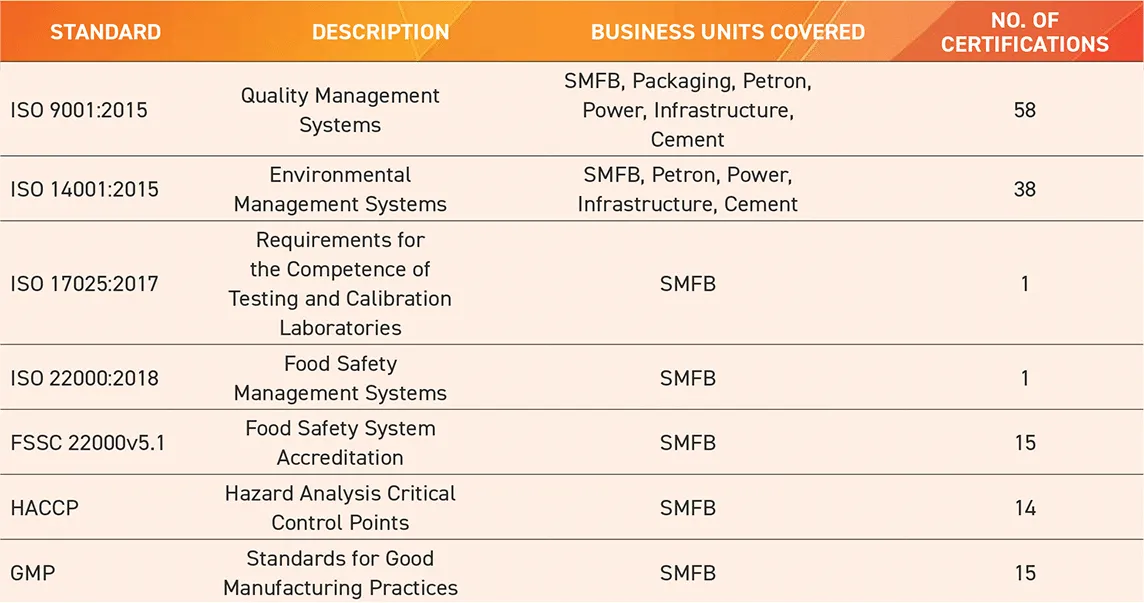

The Company’s commitment to deliver quality products and services, and not cause any harm to people and the environment, is demonstrated by its ISO and Food Safety certifications, of which there were 134 installations with valid certificates as of the end of December 2022.

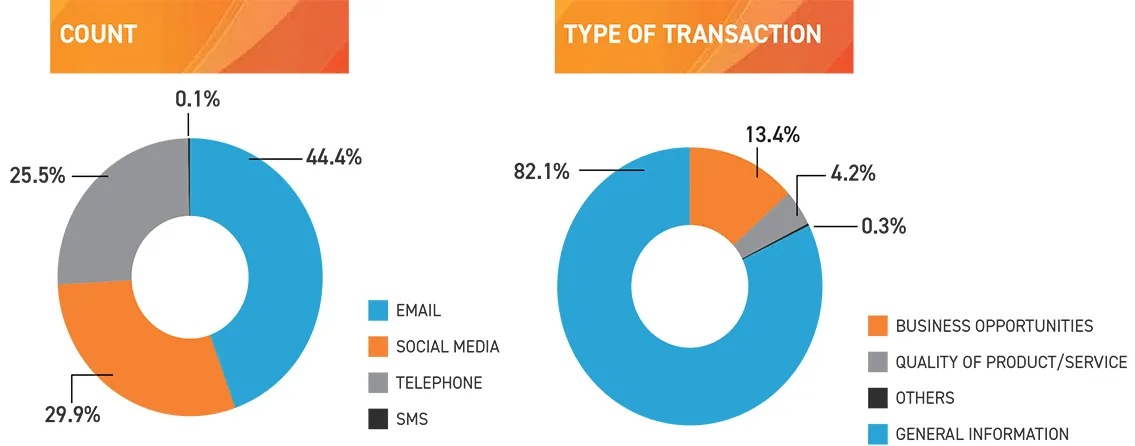

Gathering and addressing product complaints is another essential element in ensuring customer welfare. The Company has a Customer Care Hotline +632 8632-2000 which is staffed by SMITS subsidiary, ProSync. We have a San Miguel Corporation Facebook page, various Facebook brand pages, company websites and email addresses through which customers the video footage to assess the requirements for signages, their proper placement and categorization, the presence of hazardous items, and other safety-related issues. Through these parameters and procedures, the organization can then ensure safer and more convenient road use for motorists. The Company’s commitment to deliver quality products and services, and not cause any harm to people and the environment, is demonstrated by its ISO and Food Safety certifications, of which there were 134 installations with valid certificates as of the end of December 2022. and other individuals send in complaints, inquiries, and other feedback. ProSync sorts the information and sends these to the respective contact persons in charge of each business. We also employ social media monitoring tools to track any issues or posts mentioning San Miguel or our brands.

Customer complaints about food, in particular, are managed by Quality Assurance specialists following a standardized procedure, with the goal of resolving them within 24 hours. In addition to their technical knowledge about the products, the specialists are given soft skills training to listen, empathize, and properly interact with customers. An escalation protocol is defined should it be necessary to involve levels of management to settle issues. The organization appreciates that customer complaints and feedback are opportunities to identify areas for improvement and further strengthen food safety controls in place.